Celebrating ten years back home at 28° 19′ N by 80° 36′ W!

This year marks my tenth anniversary of returning home. It’s mind-boggling, really, that it’s been that long, but then again, it’s pretty hard to believe that next year will mark my seventh year of existence here on Mother Earth.

As noted elsewhere, I developed a passion for woodworking early. In my first ‘garage/shop’ in Washington, I proudly displayed a hand-lettered sign that said:

He With The Most Toys Wins!

When I moved to Germany in 1987, I closed shop until my return three years later. I had moved back to Colorado and was living the dream, traveling around the world and working at Hewlett-Packard’s corporate machine. I outfitted my basement as my first dedicated woodworking shop with new stationary tools. There was an excellent lumber store in Fort Collins. I used our most excellent 2D CAD system—ME 10—and started designing and building the furniture for my new home in the Rockies.

For a while, I thought Colorado might be my new home. I liked it there. Unfortunately, the job was changing fast, and I found myself on the outside looking in. In a stunning display of madness, I made a sharp right turn and ended up in Atlanta for nearly 19 years. The last 15 years were spent as a different version of myself, constantly at odds with the part I left on the left coast.

When I finally escaped the madness, I ended up back where it started: Cocoa Beach. I was home and have now lived here longer than anywhere else. I had envisioned this day for decades, which was one reason I moved to the Southeast in the mid-1990s. After I retired in 2020, I built a dedicated shop in my backyard.

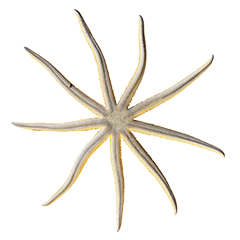

Before I escaped, I had to refinish that first piece of furniture that I built for myself (and still owned). I screwed up and sanded through the teak veneer while refinishing it. After moving back, I had an idea to replace the top with a compass rose with the position of Cocoa Beach on it. It was on my list for over ten years before I acted.

When I first saw the Shaper Origin router demonstrated several years ago, it showed a craftsman using it to inlay a compass rose on a hardwood floor. That is precisely what I was looking for! My comments concerning this incredible tool are elsewhere.

Build

I created the base layout using AutoCAD, imported it into Shaper Studio, and added the lettering.

My idea was to use walnut and maple for the rose pieces and zebrawood for the ring segments. The background would be quarter-sawn mahogany, and the lettering would be maple.

The lettering capabilities had recently been upgraded, and I found a simple letter font that worked well for inlay. There is no lettering on a curve capability yet, but manually rotating the letters worked well enough.

I quickly learned that paying attention to the jig used to lay out the optical tape for the router pays off. I try to keep everything coplanar and provide surfaces for moving the tape smoothly. Once a good set of markers is established, I am always stunned at the router’s accuracy and repeatability.

The first step is to cut the main layout, which is cut precisely as designed. Offset is added when cutting the ‘puzzle’ pieces to facilitate assembly.

Double-sided tape keeps the pieces in place, and the through cuts are made. The cut pieces are easily removed by gently lifting them with a small, smooth pry bar.

The next step was to cut out the interior pieces. I used the Shaper Workstation to do this. I learned that adding about 0.005″ inch offset to make these pieces undersized made for easy placement with no sacrifice in appearance.

The next step was new for me and involved cutting the letters directly out of 0.030″ wood veneer with a paper backing. The letters were small, too, especially some of the symbols. I held the veneer with double-sided tape and cut the letters to size. I was impressed at how resilient the cut letters were when removing them from the tape and cleaning the edges. It was much easier than I anticipated.

The final step was to add the coordinates. I used the original larger design to facilitate cutting the pockets for the individual letters. I was impressed with how accurately I could set up the tool paths using visual references.

Cutting the slightly smaller letters, including the small degree and minute symbol, was no problem. I glued each one in as I cut them. This was, again, much easier than I anticipated.

The final step was to cut to size and add the outer edge. I used Paduak for this, which I thought made the piece pop.